- Home Page

- Company Profile

-

Our Products

- Industrial Burners

- Light Oil Burner

- FG 10 Single Stage Light Oil Burner

- FG 14 Single Stage Light Oil Burner

- G 1S Single Stage Light Oil Burner

- GL 20 Single Stage Light Oil Burner

- GL 30 Single Stage Light Oil Burner

- FG 40-2 2 Stage Light Oil Burner

- FG 60-2 2 Stage Light Oil Burner

- FGP 100-2 2 Stage Light Oil Burner

- FGP 120-2 2 Stage Light Oil Burner

- FGP 150-2 2 Stage Light Oil Burner

- FGP 50-2 2 Stage Light Oil Burner

- FGP 70-2 2 Stage Light Oil Burner

- G 2S 2 Stage Light Oil Burner

- FGP 190-3 3 Stage Light Oil Burner

- FGP 250-3 3 Stage Light Oil Burner

- FGP 350-3 3 Stage Light Oil Burner

- FGP 450-3 3 Stage Light Oil Burner

- GX3 3 Stage Light Oil Burner

- Industrial Heavy Oil Burner

- Industrial Gas Burners

- Suntec Fuel Pumps

- Suntec Fuel Pump

- Suntec Fuel Pumps

- Suntec Pump

- Burner Fuel Pump

- Fuel Pump For Industrial Burner

- Suntec Industrial Fuel Pump

- Suntec Oil Burners Pump

- Suntec Industrial Oil Pump

- Suntec Fuel Oil Pumps

- Suntec Fuel Oil Gear Pump

- Suntec Burner Pump

- Suntec AN67B 7251 4P Pump

- TA2C 40107 Suntec Pump

- T3C 106 Suntec Pumps

- E7NA 1069 7P Suntec Pumps

- Hot Water Generator

- Baby Steam Boilers

- Burner Gas Train System

- Siemens Oil Burner Controls

- Siemens Gas Burner Controls

- Siemens Universal Controller

- Industrial Burner Servo Motors

- Gas Governor

- Honeywell Combustion Control Products

- Compact Flame Detector

- Flame Switch Units

- Honeywell Flame Detectors

- Integrated Flame Switches

- Electronic Flame Detector

- Infrared Flame Detector

- Honeywell Flame Detection

- Burner Control System

- Honeywell Burner Control

- Honeywell Wiring Subbase

- Purge Timers

- Honeywell Satronic Burner Controls

- Satronic Burner Controls

- Honewell Satronic Burners Controls For Single Gas

- Photo Cell Flame Detectors

- Sequence Controllers

- Electronic Ignition Devices

- Oil Preheaters

- Conectron Servomotors

- Fuel Delivery System

- Fuel Air Control System

- Pressure Controllers

- Pressure Control For Regulation Of Liquid

- Modutrol Motors

- Spark Ignition Module

- Ignition Transformers for industrial burners

- Fuel Pump For Industrial Burner

- Industrial Gas Regulators

- Motors For Industrial Burners

- Water Boiler

- Burners Controllers

- Solenoid Valves For Industrial Burners

- Servomotors Assembly

- Conectron Motors

- Conectron Servo Motors

- Conectron Air Damper Actuator

- Honeywell Motors

- Siemens Reversing Actuator

- Honewell Servomotors Assembly

- Siemens Servo Motor Dampers Actuators

- Siemens Damper Actuators

- Siemens Actuators

- Siemens Servo Motors

- Siemens Actuators For Oil

- High Speed Damper Actuators

- Siemens SQM9 Actuators

- Siemens Servo Motor Damper Actuators

- Industrial Pressure Switches

- Industrial Burners Nozzles

- Burners Control Box & Base Plate

- Flame Sensor/Photo Cell/UVCell Industrial Burners

- Siemens Burners Photocell

- Industrial Burners UV Cell

- Brahma Photo Cell

- Danfoss Flame Sensors

- Siemens Gas UV Cell

- ECEE Burners Photo Cell

- Siemens Flame Detector

- Siemens Burner Flame Detector

- Blue Flame Detector

- Siemens UV Flame Detectors

- Siemens Flame Sensor

- Siemens UV Photocell

- Siemens Flame UV Cell

- QRI Flame Detectors

- Siemens Flame Sensor RAR

- Siemens Oxygen Sensor

- Burners Diffuser Disc

- Burner Ignition Electrode

- Industrial Burner Filters

- Industrial Burners Pressure Gauges

- Industrial Burners Couplings

- Industrial Burner Connectors

- Burners Thermostat

- Gas Valves

- Our Infrastructure

- Contact Us

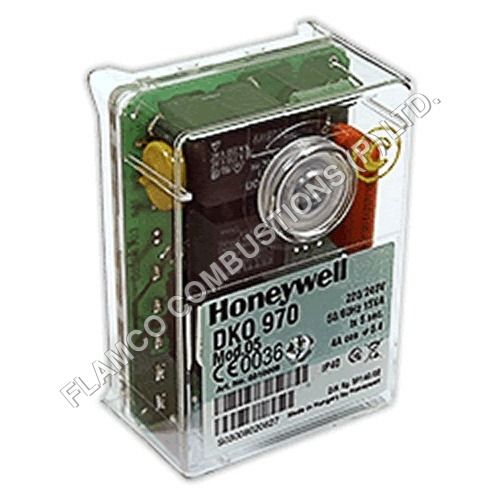

Flame Switch Units

Product Details:

- Max Pressure 10 Bar

- Function Flame Detection and Switch Control

- Mechanical Life >1 Million Operations

- Thread size G1/2 BSP

- Working Temperature -20C to 80C

- Product Type Flame Switch Unit

- Max. Current 16A

- Click to View more

X

Flame Switch Units Price And Quantity

- 100-200 Piece

Flame Switch Units Product Specifications

- 110mm x 65mm x 60mm

- 0.5 to 10 Bar

- 250V AC

- 3500W

- 320g

- Flame Detection and Switch Control

- 10 Bar

- Black & Silver

- >1 Million Operations

- G1/2 BSP

- IP65

- Relay Output (NO/NC)

- -20C to 80C

- Flame Switch Unit

- 16A

- Industrial Burner Safety Control, Oil/Gas Burner Management

Flame Switch Units Trade Information

- 1000 Piece Per Week

- 1 Week

Product Description

Flame Switch Units

Model No - C 7076

Model C 7076 is a solid state dynamic self check adjustable sensitivity flame detector , used with compatible Honewell flame safe guard controls and amplifier . This is recommended for off - process fuels , such as H2S or flames that are difficult to detect . eg. Coal , BF , Producer gas etc.

Exceptional Performance, Fast Response

Engineered for precision and speed, the Flame Switch Unit detects flame presence in under one second, facilitating immediate safety responses. Its robust relay output (NO/NC) ensures secure burner management, while the devices mechanical durability exceeds one million operations. This unit is essential for critical industrial environments where quick intervention enhances operational safety.

Industrial-Grade Build and Versatile Mounting

Constructed with a combination of ABS and aluminum, the unit is designed for longevity and resistance to harsh conditions. Suitable for both panel and surface mount configurations, this flame switch is optimized for seamless integration into diverse industrial settings. The compact design, paired with an IP65 rating, enables flexible, protected installation.

Comprehensive Compliance and User-Friendly Operation

Adhering strictly to EN298 standards, this flame switch unit meets the demands of modern industrial environments. Users benefit from features like LED status indicators, manual or automatic reset options, and straightforward screw terminal connections. The devices clear design focus ensures safe, efficient burner management with reliable electrical safety.

FAQs of Flame Switch Units:

Q: How does the flame switch unit enhance burner safety in industrial settings?

A: The flame switch unit detects the presence or absence of a flame almost instantaneously (in less than 1 second). Upon detection of unsafe conditions, it actuates a relay output to switch off the burner, preventing hazardous situations and ensuring continuous industrial safety.Q: What types of burners or applications is this unit suitable for?

A: Designed specifically for industrial environments, this unit is ideal for oil and gas burner management, as well as broader industrial burner safety control systems, thanks to its robust build, rapid response, and compliance with EN298 standards.Q: When should the manual or automatic reset option be used?

A: Manual reset is often chosen when additional safety checks are required before restarting the system after a flame fault. The automatic reset option can be used where rapid, unattended recovery is preferred, depending on operational protocols and safety requirements.Q: Where is the optimal location to mount this flame switch unit?

A: Mounting should be on a panel or suitable surface nearby the burner system, ensuring the unit remains within easy access for monitoring LED indicators and performing resets, while also taking advantage of the devices IP65 rating for dust and water ingress protection.Q: What is the process for connecting the flame switch unit to a system?

A: Connection is straightforward via screw terminals, which accommodate secure and reliable wiring to the power supply and output relays. Always ensure voltage and load ratings (up to 250V AC, 16A) are matched to the system requirements.Q: How does the LED status indicator benefit system operators?

A: The integrated LED status indicator provides immediate, visual confirmation of flame presence and operational state, enabling rapid diagnostics and minimizing downtime in case of system events or faults.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Honeywell Combustion Control Products ' category

|

Kolkata Office

S.L. Sarani,

Gautam Para, Baguiati

Kolkata-700059 ( India )

|

Bangalore Office

No. 11, Old No.298,

9th 'A' Main, 1st Corss,

Chairman Layout, Dodda Bansawadi,

Opp. Shrinidhi Upachar Hotel ,

Bangalore-560043 ( India )

|

|

Ludhiana Office

House No. 3721, Gali No. 7,

Baba Deep Singh Nagar,

Opp.Transport Nagar,

Ludhiana,Punjab,( India )

|

Mumbai Office

Flat No. B/001, Ground Floor,

Krishna Sagar Apartment, Link Road,

Nallasopara, Vasant Nagar,

Vasai (E) Thane-401209

Maharashtra , ( India )

|