- Home Page

- Company Profile

-

Our Products

- Industrial Burners

- Light Oil Burner

- FG 10 Single Stage Light Oil Burner

- FG 14 Single Stage Light Oil Burner

- G 1S Single Stage Light Oil Burner

- GL 20 Single Stage Light Oil Burner

- GL 30 Single Stage Light Oil Burner

- FG 40-2 2 Stage Light Oil Burner

- FG 60-2 2 Stage Light Oil Burner

- FGP 100-2 2 Stage Light Oil Burner

- FGP 120-2 2 Stage Light Oil Burner

- FGP 150-2 2 Stage Light Oil Burner

- FGP 50-2 2 Stage Light Oil Burner

- FGP 70-2 2 Stage Light Oil Burner

- G 2S 2 Stage Light Oil Burner

- FGP 190-3 3 Stage Light Oil Burner

- FGP 250-3 3 Stage Light Oil Burner

- FGP 350-3 3 Stage Light Oil Burner

- FGP 450-3 3 Stage Light Oil Burner

- GX3 3 Stage Light Oil Burner

- Industrial Heavy Oil Burner

- Industrial Gas Burners

- Suntec Fuel Pumps

- Suntec Fuel Pump

- Suntec Fuel Pumps

- Suntec Pump

- Burner Fuel Pump

- Fuel Pump For Industrial Burner

- Suntec Industrial Fuel Pump

- Suntec Oil Burners Pump

- Suntec Industrial Oil Pump

- Suntec Fuel Oil Pumps

- Suntec Fuel Oil Gear Pump

- Suntec Burner Pump

- Suntec AN67B 7251 4P Pump

- TA2C 40107 Suntec Pump

- T3C 106 Suntec Pumps

- E7NA 1069 7P Suntec Pumps

- Hot Water Generator

- Baby Steam Boilers

- Burner Gas Train System

- Siemens Oil Burner Controls

- Siemens Gas Burner Controls

- Siemens Universal Controller

- Industrial Burner Servo Motors

- Gas Governor

- Honeywell Combustion Control Products

- Compact Flame Detector

- Flame Switch Units

- Honeywell Flame Detectors

- Integrated Flame Switches

- Electronic Flame Detector

- Infrared Flame Detector

- Honeywell Flame Detection

- Burner Control System

- Honeywell Burner Control

- Honeywell Wiring Subbase

- Purge Timers

- Honeywell Satronic Burner Controls

- Satronic Burner Controls

- Honewell Satronic Burners Controls For Single Gas

- Photo Cell Flame Detectors

- Sequence Controllers

- Electronic Ignition Devices

- Oil Preheaters

- Conectron Servomotors

- Fuel Delivery System

- Fuel Air Control System

- Pressure Controllers

- Pressure Control For Regulation Of Liquid

- Modutrol Motors

- Spark Ignition Module

- Ignition Transformers for industrial burners

- Fuel Pump For Industrial Burner

- Industrial Gas Regulators

- Motors For Industrial Burners

- Water Boiler

- Burners Controllers

- Solenoid Valves For Industrial Burners

- Servomotors Assembly

- Conectron Motors

- Conectron Servo Motors

- Conectron Air Damper Actuator

- Honeywell Motors

- Siemens Reversing Actuator

- Honewell Servomotors Assembly

- Siemens Servo Motor Dampers Actuators

- Siemens Damper Actuators

- Siemens Actuators

- Siemens Servo Motors

- Siemens Actuators For Oil

- High Speed Damper Actuators

- Siemens SQM9 Actuators

- Siemens Servo Motor Damper Actuators

- Industrial Pressure Switches

- Industrial Burners Nozzles

- Burners Control Box & Base Plate

- Flame Sensor/Photo Cell/UVCell Industrial Burners

- Siemens Burners Photocell

- Industrial Burners UV Cell

- Brahma Photo Cell

- Danfoss Flame Sensors

- Siemens Gas UV Cell

- ECEE Burners Photo Cell

- Siemens Flame Detector

- Siemens Burner Flame Detector

- Blue Flame Detector

- Siemens UV Flame Detectors

- Siemens Flame Sensor

- Siemens UV Photocell

- Siemens Flame UV Cell

- QRI Flame Detectors

- Siemens Flame Sensor RAR

- Siemens Oxygen Sensor

- Burners Diffuser Disc

- Burner Ignition Electrode

- Industrial Burner Filters

- Industrial Burners Pressure Gauges

- Industrial Burners Couplings

- Industrial Burner Connectors

- Burners Thermostat

- Gas Valves

- Our Infrastructure

- Contact Us

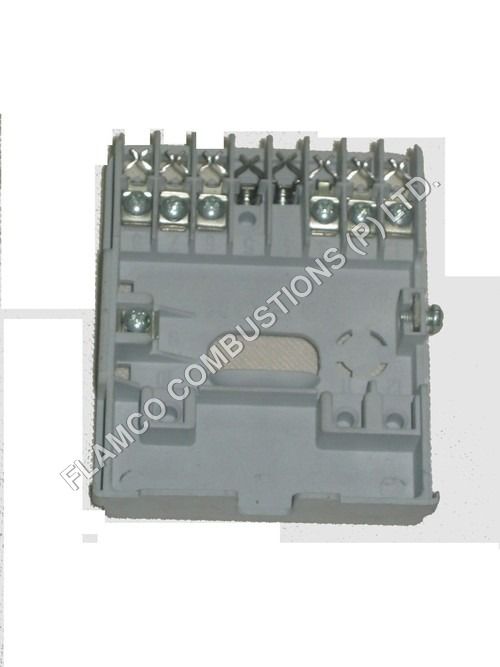

Burners Base Plate

Product Details:

- Installation Type Mounted/fixed

- Usage & Applications Industrial and commercial burner assemblies, boiler burner plates, industrial ovens

- Mounting Type Plate mounting, flanged or bolted

- Product Type Burners Base Plate

- Operating Temperature Up to 600C (approximate, depending on material)

- Working Temperature Up to 600C (estimate, varies by application)

- Diameter Approx. 150mm to 250mm (varies on model)

- Click to View more

X

Burners Base Plate Price And Quantity

- 100-200 Unit

Burners Base Plate Product Specifications

- Up to 600C (approximate, depending on material)

- Mounted/fixed

- Burners Base Plate

- Used as a base mounting plate for industrial gas or oil burners

- Plate mounting, flanged or bolted

- Up to 600C (estimate, varies by application)

- Industrial and commercial burner assemblies, boiler burner plates, industrial ovens

- Approx. 2 to 5 kg (depending on size and material)

- Custom or standard as per burner (approximate 200mm x 200mm x 10mm)

- Approx. 150mm to 250mm (varies on model)

Burners Base Plate Trade Information

- 100 Unit Per Month

- 1 Week

Product Description

To meet the different needs of the clients with utmost proficiency, we are engaged in exporting a quality grade Burners Base Plate. These plates are manufactured by most trusted and authorized vendors, from whom we obtain with the help of our expert procuring agents. The clients can avail our plates in different customized specifications as per their requirements. We offer the Burners Base Plate to the clients at the cost effective prices.

Features:

- Highly efficient

- Long lasting

- Quality approved

Why Us?

- Standard quality

- Competitive prices

- On-time delivery

- Assured customer satisfaction

- Wide distribution network

Precision Engineering for Optimal Performance

Each base plate is produced using advanced CNC machining and laser cutting techniques, ensuring precisely located holes and smooth, safe edges. This attention to detail guarantees a perfect fit and secure mounting for a range of burner assemblies across industrial and commercial applications.

Customizable to Fit Any Burner Model

With flexibility in sizing, hole configuration, thickness, and finish, the Burners Base Plate easily adapts to any major burner model requirements. Customization ensures seamless integration with your specific burner assemblies, whether for new installations or retrofit projects.

Long-Lasting and Corrosion-Resistant

Manufactured from quality materials and treated for corrosion resistance, these plates are built for longevity under tough industrial environments. They maintain their structural integrity and finish even at high operating temperatures for an extended service life.

FAQs of Burners Base Plate:

Q: How is the Burners Base Plate installed in an industrial burner assembly?

A: The base plate is designed for straightforward mounting via plate, flanged, or bolted approaches. Its precision holes align seamlessly with burner mounting points, simplifying secure installation in boilers, ovens, or other industrial equipment.Q: What customization options are available for the Burners Base Plate?

A: You can request varying sizes, thicknesses, hole patterns, and finishes, with compatibility for all major burner models. The plate can be tailored to your application, whether you need unique dimensions or specific mounting arrangements.Q: When should I choose a custom base plate over a standard model?

A: Custom plates are ideal when standard options do not match your burners specifications, such as unique spacing, special hole patterns, or non-standard dimensions. Customization ensures optimal fit and safe operation for specialized or older equipment.Q: Where are these base plates commonly used?

A: They are primarily used in industrial and commercial settings, serving as the mounting foundation for gas or oil burners. Typical applications include industrial ovens, boiler burner assemblies, and various heater units across manufacturing plants.Q: What is the manufacturing process for these plates?

A: Each plate is manufactured using advanced CNC machining or laser cutting technology, ensuring precision and consistency in hole placement and finish. After shaping, all edges are deburred for safety, and optional corrosion-resistant treatments can be applied.Q: How does the plate benefit my burner system?

A: The base plate provides a stable, secure mount with long service life and high temperature resilience. Smooth, deburred edges enhance safety during installation and operation, while corrosion resistance ensures sustained reliability in industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Burners Control Box & Base Plate ' category

|

Kolkata Office

S.L. Sarani,

Gautam Para, Baguiati

Kolkata-700059 ( India )

|

Bangalore Office

No. 11, Old No.298,

9th 'A' Main, 1st Corss,

Chairman Layout, Dodda Bansawadi,

Opp. Shrinidhi Upachar Hotel ,

Bangalore-560043 ( India )

|

|

Ludhiana Office

House No. 3721, Gali No. 7,

Baba Deep Singh Nagar,

Opp.Transport Nagar,

Ludhiana,Punjab,( India )

|

Mumbai Office

Flat No. B/001, Ground Floor,

Krishna Sagar Apartment, Link Road,

Nallasopara, Vasant Nagar,

Vasai (E) Thane-401209

Maharashtra , ( India )

|