- Home Page

- Company Profile

-

Our Products

- Industrial Burners

- Light Oil Burner

- FG 10 Single Stage Light Oil Burner

- FG 14 Single Stage Light Oil Burner

- G 1S Single Stage Light Oil Burner

- GL 20 Single Stage Light Oil Burner

- GL 30 Single Stage Light Oil Burner

- FG 40-2 2 Stage Light Oil Burner

- FG 60-2 2 Stage Light Oil Burner

- FGP 100-2 2 Stage Light Oil Burner

- FGP 120-2 2 Stage Light Oil Burner

- FGP 150-2 2 Stage Light Oil Burner

- FGP 50-2 2 Stage Light Oil Burner

- FGP 70-2 2 Stage Light Oil Burner

- G 2S 2 Stage Light Oil Burner

- FGP 190-3 3 Stage Light Oil Burner

- FGP 250-3 3 Stage Light Oil Burner

- FGP 350-3 3 Stage Light Oil Burner

- FGP 450-3 3 Stage Light Oil Burner

- GX3 3 Stage Light Oil Burner

- Industrial Heavy Oil Burner

- Industrial Gas Burners

- Suntec Fuel Pumps

- Suntec Fuel Pump

- Suntec Fuel Pumps

- Suntec Pump

- Burner Fuel Pump

- Fuel Pump For Industrial Burner

- Suntec Industrial Fuel Pump

- Suntec Oil Burners Pump

- Suntec Industrial Oil Pump

- Suntec Fuel Oil Pumps

- Suntec Fuel Oil Gear Pump

- Suntec Burner Pump

- Suntec AN67B 7251 4P Pump

- TA2C 40107 Suntec Pump

- T3C 106 Suntec Pumps

- E7NA 1069 7P Suntec Pumps

- Hot Water Generator

- Baby Steam Boilers

- Burner Gas Train System

- Siemens Oil Burner Controls

- Siemens Gas Burner Controls

- Siemens Universal Controller

- Industrial Burner Servo Motors

- Gas Governor

- Honeywell Combustion Control Products

- Compact Flame Detector

- Flame Switch Units

- Honeywell Flame Detectors

- Integrated Flame Switches

- Electronic Flame Detector

- Infrared Flame Detector

- Honeywell Flame Detection

- Burner Control System

- Honeywell Burner Control

- Honeywell Wiring Subbase

- Purge Timers

- Honeywell Satronic Burner Controls

- Satronic Burner Controls

- Honewell Satronic Burners Controls For Single Gas

- Photo Cell Flame Detectors

- Sequence Controllers

- Electronic Ignition Devices

- Oil Preheaters

- Conectron Servomotors

- Fuel Delivery System

- Fuel Air Control System

- Pressure Controllers

- Pressure Control For Regulation Of Liquid

- Modutrol Motors

- Spark Ignition Module

- Ignition Transformers for industrial burners

- Fuel Pump For Industrial Burner

- Industrial Gas Regulators

- Motors For Industrial Burners

- Water Boiler

- Burners Controllers

- Solenoid Valves For Industrial Burners

- Servomotors Assembly

- Conectron Motors

- Conectron Servo Motors

- Conectron Air Damper Actuator

- Honeywell Motors

- Siemens Reversing Actuator

- Honewell Servomotors Assembly

- Siemens Servo Motor Dampers Actuators

- Siemens Damper Actuators

- Siemens Actuators

- Siemens Servo Motors

- Siemens Actuators For Oil

- High Speed Damper Actuators

- Siemens SQM9 Actuators

- Siemens Servo Motor Damper Actuators

- Industrial Pressure Switches

- Industrial Burners Nozzles

- Burners Control Box & Base Plate

- Flame Sensor/Photo Cell/UVCell Industrial Burners

- Siemens Burners Photocell

- Industrial Burners UV Cell

- Brahma Photo Cell

- Danfoss Flame Sensors

- Siemens Gas UV Cell

- ECEE Burners Photo Cell

- Siemens Flame Detector

- Siemens Burner Flame Detector

- Blue Flame Detector

- Siemens UV Flame Detectors

- Siemens Flame Sensor

- Siemens UV Photocell

- Siemens Flame UV Cell

- QRI Flame Detectors

- Siemens Flame Sensor RAR

- Siemens Oxygen Sensor

- Burners Diffuser Disc

- Burner Ignition Electrode

- Industrial Burner Filters

- Industrial Burners Pressure Gauges

- Industrial Burners Couplings

- Industrial Burner Connectors

- Burners Thermostat

- Gas Valves

- Our Infrastructure

- Contact Us

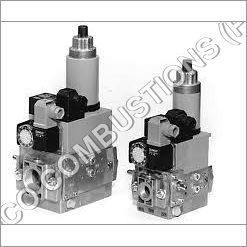

Gas Multibloc Gas Air Ratio Control

Product Details:

- Frequency 50/60 Hz

- Sensor Type Integrated Pressure Sensor

- Installation Type Horizontal or Vertical

- Current max. 0.5A per valve

- Output 2-stage / Modulating Valve Output

- Protection Level IP54

- Measuring Range 10 mbar to 500 mbar

- Click to View more

X

Gas Multibloc Gas Air Ratio Control Price And Quantity

- 100-200 Unit

Gas Multibloc Gas Air Ratio Control Product Specifications

- max. 0.5A per valve

- dep. on model, e.g. 250x150x180 mm

- approx. 2.5 kg

- -15C to +60C

- DN15-DN65

- Industrial Gas Burners, Boilers, Furnaces

- Integrated Pressure Sensor

- Horizontal or Vertical

- 50/60 Hz

- -15C to +60C

- None (mechanical adjustment)

- 230V AC

- IP54

- 2% F.S.

- 10 mbar to 500 mbar

- Inlet / Outlet / Differential

- Gas Multibloc Gas Air Ratio Control

- 2-stage / Modulating Valve Output

- 230V AC

Gas Multibloc Gas Air Ratio Control Trade Information

- 100 Unit Per Month

- 1 Week

Product Description

Gas Multibloc Gas Air Ratio Control

- Max. Operating pressure

- 0.36 bar (36 kPa )

- Gas - air - mixture regulation with variable ratio in range 0.75 :1 to 3:1

- Other ratio range on request

- Infinitely variable operation

- Furnace chamber pressure compensation

- Zero - point correction

- EC type test approval as per EC Gas Appliance Directive :

- MB-VEF...B01 CE-0085 AN 2802

- EC type test approval as per EC Pressure Equipment Directive :

MB-VEF...B01 CE0036 - Approvals in other important gas consuming countries .

Technical Specification

| EC Approval | Available |

| Max. Operating pressure | 0.36 bar (36 kPa ) |

| Material used | SS, MS |

| Gas - air - mixture ratio | 0.75 :1 to 3:1 |

Precision Ratio Control for Combustion Systems

Maintain optimal performance with the Gas Multiblocs integrated air/gas ratio adjuster and automatic shut-off valves, supporting controlled combustion and improved energy efficiency. The built-in pressure regulator and modulating valve output facilitate precise fuel delivery for industrial applications, maximizing safety and reliability.

Durable, Compact Design for Versatile Installation

The Multibloc is engineered with an IP54 protection rating, aluminum body, and brass internals, ensuring long-term durability despite harsh environments. Its compact footprint and dual mounting options (threaded or flanged) enable flexible horizontal or vertical installation for space-constrained setups.

Effortless Service and Compliance

Certified to EN 161, Class A, and CE standards, the Multibloc is easy to install, service, and maintain, reducing operational downtime. Its accessible mechanical adjustment and optional manual reset are designed to support safe routine checks while ensuring compliance with industry requirements.

FAQs of Gas Multibloc Gas Air Ratio Control:

Q: How does the integrated air/gas ratio adjuster enhance combustion system efficiency?

A: The air/gas ratio adjuster ensures precise mixing of fuel and air, leading to more efficient combustion, better energy use, and reduced emissions for industrial gas-fired equipment.Q: What applications are suitable for the Gas Multibloc?

A: This product is ideal for use in combustion system control, including industrial gas burners, boilers, and furnaces across manufacturing, processing, and utility operations.Q: When is the manual reset option required during operation?

A: The manual reset is typically used after a safety shut-off event. It ensures the system cannot be automatically restarted without a deliberate manual check, improving safety in critical processes.Q: Where should the Multibloc be installed to ensure maximum protection and functionality?

A: For optimal performance and conformity with its IP54 rating, install the Multibloc in areas shielded from excessive moisture or dust, using either horizontal or vertical mounting depending on your system layout.Q: What is the process for commissioning and servicing the Multibloc?

A: Commissioning involves connecting the wiring via the terminal block, adjusting the air/gas ratio mechanically, and verifying pressure settings. Servicing is straightforward due to the compact design and integrated pressure sensor.Q: How does the double pole switch function for twin-valve configurations?

A: In twin-valve setups, the double pole switch independently controls both safety shut-off valves, sharply enhancing system reliability and facilitating staged or modulating outputs.Q: What are the benefits of the Gas Multiblocs rugged aluminum and brass construction?

A: Its aluminum body and brass internals offer superior durability and resistance to corrosion, contributing to long service life and reliable performance in demanding industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Burners Control Box & Base Plate ' category

|

Kolkata Office

S.L. Sarani,

Gautam Para, Baguiati

Kolkata-700059 ( India )

|

Bangalore Office

No. 11, Old No.298,

9th 'A' Main, 1st Corss,

Chairman Layout, Dodda Bansawadi,

Opp. Shrinidhi Upachar Hotel ,

Bangalore-560043 ( India )

|

|

Ludhiana Office

House No. 3721, Gali No. 7,

Baba Deep Singh Nagar,

Opp.Transport Nagar,

Ludhiana,Punjab,( India )

|

Mumbai Office

Flat No. B/001, Ground Floor,

Krishna Sagar Apartment, Link Road,

Nallasopara, Vasant Nagar,

Vasai (E) Thane-401209

Maharashtra , ( India )

|