- Home Page

- Company Profile

-

Our Products

- Industrial Burners

- Light Oil Burner

- FG 10 Single Stage Light Oil Burner

- FG 14 Single Stage Light Oil Burner

- G 1S Single Stage Light Oil Burner

- GL 20 Single Stage Light Oil Burner

- GL 30 Single Stage Light Oil Burner

- FG 40-2 2 Stage Light Oil Burner

- FG 60-2 2 Stage Light Oil Burner

- FGP 100-2 2 Stage Light Oil Burner

- FGP 120-2 2 Stage Light Oil Burner

- FGP 150-2 2 Stage Light Oil Burner

- FGP 50-2 2 Stage Light Oil Burner

- FGP 70-2 2 Stage Light Oil Burner

- G 2S 2 Stage Light Oil Burner

- FGP 190-3 3 Stage Light Oil Burner

- FGP 250-3 3 Stage Light Oil Burner

- FGP 350-3 3 Stage Light Oil Burner

- FGP 450-3 3 Stage Light Oil Burner

- GX3 3 Stage Light Oil Burner

- Industrial Heavy Oil Burner

- Industrial Gas Burners

- Suntec Fuel Pumps

- Suntec Fuel Pump

- Suntec Fuel Pumps

- Suntec Pump

- Burner Fuel Pump

- Fuel Pump For Industrial Burner

- Suntec Industrial Fuel Pump

- Suntec Oil Burners Pump

- Suntec Industrial Oil Pump

- Suntec Fuel Oil Pumps

- Suntec Fuel Oil Gear Pump

- Suntec Burner Pump

- Suntec AN67B 7251 4P Pump

- TA2C 40107 Suntec Pump

- T3C 106 Suntec Pumps

- E7NA 1069 7P Suntec Pumps

- Hot Water Generator

- Baby Steam Boilers

- Burner Gas Train System

- Siemens Oil Burner Controls

- Siemens Gas Burner Controls

- Siemens Universal Controller

- Industrial Burner Servo Motors

- Gas Governor

- Honeywell Combustion Control Products

- Compact Flame Detector

- Flame Switch Units

- Honeywell Flame Detectors

- Integrated Flame Switches

- Electronic Flame Detector

- Infrared Flame Detector

- Honeywell Flame Detection

- Burner Control System

- Honeywell Burner Control

- Honeywell Wiring Subbase

- Purge Timers

- Honeywell Satronic Burner Controls

- Satronic Burner Controls

- Honewell Satronic Burners Controls For Single Gas

- Photo Cell Flame Detectors

- Sequence Controllers

- Electronic Ignition Devices

- Oil Preheaters

- Conectron Servomotors

- Fuel Delivery System

- Fuel Air Control System

- Pressure Controllers

- Pressure Control For Regulation Of Liquid

- Modutrol Motors

- Spark Ignition Module

- Ignition Transformers for industrial burners

- Fuel Pump For Industrial Burner

- Industrial Gas Regulators

- Motors For Industrial Burners

- Water Boiler

- Burners Controllers

- Solenoid Valves For Industrial Burners

- Servomotors Assembly

- Conectron Motors

- Conectron Servo Motors

- Conectron Air Damper Actuator

- Honeywell Motors

- Siemens Reversing Actuator

- Siemens Servo Motor Dampers Actuators

- Honewell Servomotors Assembly

- Siemens Damper Actuators

- Siemens Actuators

- Siemens Servo Motors

- Siemens Actuators For Oil

- High Speed Damper Actuators

- Siemens SQM9 Actuators

- Siemens Servo Motor Damper Actuators

- Industrial Pressure Switches

- Industrial Burners Nozzles

- Burners Control Box & Base Plate

- Flame Sensor/Photo Cell/UVCell Industrial Burners

- Siemens Burners Photocell

- Industrial Burners UV Cell

- Brahma Photo Cell

- Danfoss Flame Sensors

- Siemens Gas UV Cell

- ECEE Burners Photo Cell

- Siemens Flame Detector

- Siemens Burner Flame Detector

- Blue Flame Detector

- Siemens UV Flame Detectors

- Siemens Flame Sensor

- Siemens UV Photocell

- Siemens Flame UV Cell

- QRI Flame Detectors

- Siemens Flame Sensor RAR

- Siemens Oxygen Sensor

- Burners Diffuser Disc

- Burner Ignition Electrode

- Industrial Burner Filters

- Industrial Burners Pressure Gauges

- Industrial Burners Couplings

- Industrial Burner Connectors

- Burners Thermostat

- Gas Valves

- Our Infrastructure

- Contact Us

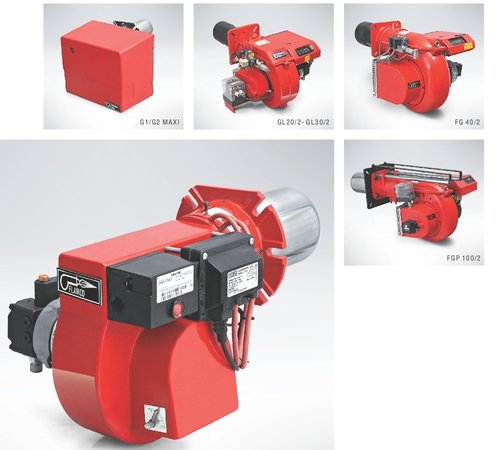

Industrial Oil Burners

14000 INR/Piece

Product Details:

- Condition New

- Type Oil Burner

- Usage Industrial

- Structure Monoblock

- Pressure Medium Pressure

- Style Horizontal

- Material Cast Iron

- Click to View more

X

Industrial Oil Burners Price And Quantity

- 14000 INR/Piece

- 100-200 Piece

Industrial Oil Burners Product Specifications

- Cast Iron

- Oil Burner

- New

- Industrial

- Monoblock

- Horizontal

- Medium Pressure

Industrial Oil Burners Trade Information

- 100 Piece Per Week

- 1 Week

Product Description

Ours is a trusted name engaged in trading and exporting the best grade Industrial Gas Burner for our clients. Our offered burners find a host of applications in various oil and gas industrial applications. We procure these burners from some of the most trusted and reputed names of the market who fabricate these burners using best quality raw material. In addition to this, our vendors manufacture these burners in accordance to the variegated requirements of our customers and in compliance to the prevailing norms and regulations of this industry. Our offered Industrial Gas Burner are reckoned for the following features:- Precision engineering

- Reliable performance

- Longer service life

- Smooth operations

OVERALL DIMENSIONS (mm)

|

MODEL |

Output |

|

Output |

|

|

Dimensions |

|

|

|

|

|

|

|

|

|

|

|

|

Kg/h |

|

KW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Min |

Max |

Min |

Max |

A |

B |

|

TC |

TL |

E |

F |

D |

I |

L |

M |

N |

|

G OS |

2 |

3.3 |

23.7 |

39.1 |

137 |

137 |

80 |

112 |

152 |

215 |

169 |

233 |

160 |

130 |

M8 |

90 |

|

G 1S, 1.22 |

2 |

5 |

23.7 |

59.2 |

137 |

137 |

85 |

112 |

152 |

292 |

169 |

265 |

160 |

130 |

M8 |

95 |

|

G 2S, 2.22 |

4 |

9.8 |

47.3 |

116 |

157 |

170 |

90 |

112 |

152 |

265 |

210 |

265 |

160 |

130 |

M8 |

100 |

|

GX3, 3.22 |

7 |

15 |

83 |

178 |

179 |

189 |

110 |

130 |

250 |

298 |

248 |

306 |

226 |

160 |

M8 |

120 |

|

FG-10 |

4 |

10 |

47.3 |

118.3 |

115 |

210 |

110 |

130 |

250 |

205 |

80 |

300 |

140 |

165 |

M8 |

120 |

|

FG-14 |

7 |

14 |

82.8 |

165.6 |

115 |

210 |

110 |

130 |

250 |

205 |

80 |

300 |

140 |

165 |

M8 |

120 |

|

GL-20, 20/2 |

10 |

20 |

118 |

236 |

175 |

230 |

125 |

130 |

250 |

230 |

100 |

390 |

170 |

226 |

M10 |

135 |

|

GL-30, 30/2 |

13 |

30 |

153 |

355 |

175 |

240 |

130 |

130 |

250 |

230 |

100 |

390 |

170 |

226 |

M10 |

140 |

|

FG 40/2 |

20 |

40 |

235 |

470 |

180 |

340 |

150 |

250 |

335 |

330 |

70 |

493 |

160 |

160 |

M10 |

160 |

|

FGP 50/2 |

20 |

50 |

236.5 |

592 |

188 |

324 |

150 |

250 |

335 |

327 |

90 |

493 |

226 |

205 |

M10 |

160 |

|

FG 60/2 |

30 |

60 |

355 |

696 |

180 |

340 |

150 |

250 |

335 |

330 |

70 |

493 |

160 |

160 |

M10 |

160 |

|

FGP 70/2 |

35 |

70 |

406 |

812 |

250 |

310 |

165 |

170 |

330 |

327 |

170 |

660 |

368 |

340 |

M12 |

180 |

|

FGP 100/2 |

40 |

100 |

464 |

1160 |

300 |

350 |

175 |

200 |

450 |

438 |

170 |

670 |

368 |

340 |

M12 |

190 |

|

FGP 100/2 |

60 |

120 |

969 |

1392 |

350 |

380 |

212 |

200 |

400 |

438 |

213 |

820 |

368 |

340 |

M14 |

230 |

|

FGP 150/2 |

75 |

150 |

870 |

1740 |

350 |

380 |

212 |

200 |

400 |

438 |

213 |

820 |

368 |

340 |

M14 |

230 |

|

FGP 190/3 |

60 |

206 |

700 |

2390 |

429 |

429 |

232 |

495 |

|

429 |

429 |

835 |

368 |

340 |

M14 |

245 |

|

FGP 250/3 |

80 |

250 |

930 |

2900 |

429 |

460 |

269 |

500 |

|

429 |

460 |

835 |

300 |

300 |

M14 |

280 |

|

FGP 350/3 |

140 |

350 |

1620 |

4060 |

537 |

517 |

292 |

520 |

|

480 |

540 |

942 |

390 |

390 |

M14 |

355 |

|

FGP 450/3 |

160 |

450 |

1850 |

5220 |

507 |

517 |

380 |

560 |

|

480 |

540 |

942 |

390 |

390 |

M14 |

390 |

|

FGP 550/M |

200 |

550 |

2320 |

6380 |

661 |

540 |

380 |

560 |

|

481 |

540 |

1025 |

390 |

390 |

M14 |

400 |

ALL DIMENSIONS ARE APPROXIMATE AND SUBJECT TO CHANGE WITHOUT PRIOR NOTICE

Advanced Automatic Ignition & Control

Our oil burners incorporate a state-of-the-art automatic electric ignition system paired with a fully automated control panel and flame sensors. This design ensures safe and consistent operation, reducing manual intervention and optimizing fuel consumption. The control system supports a range of operation modes, adapting effortlessly to your industrial requirements.

Versatile Fuel Compatibility & Installation

Supporting light oil, heavy oil, and diesel, these burners are tailored for diverse industrial applications. With flexible mounting choicesfloor or wallyou can easily integrate the system into new or existing setups. The medium-pressure and horizontal style cast iron structure guarantee both durability and reliable performance.

Eco-Friendly Performance

Industrial Oil Burners are designed to maintain low NOx and low smoke emissions, ensuring compliance with stringent environmental standards. This low-emission performance not only supports regulatory adherence but also helps reduce your facilitys carbon footprint.

FAQs of Industrial Oil Burners:

Q: How does the automatic electric ignition system enhance burner safety and convenience?

A: The automatic electric ignition system streamlines burner startup, ensuring quick and reliable ignition without the need for manual intervention. Paired with a flame sensor, it detects and responds to flame presence for increased operational safety, reducing chances of misfires and increasing system longevity.Q: What types of fuel can these oil burners operate on?

A: These industrial burners are optimized for light oil, heavy oil, and diesel fuels, offering versatility to match various operational requirements and fuel availability in industrial environments.Q: When is it advisable to select modulating operation over single-stage or two-stage modes?

A: Modulating operation provides precise control over burner output, making it ideal for applications requiring variable heating loads and maximum energy efficiency. Single-stage and two-stage modes suit more consistent or fixed heating demands.Q: Where can these burners be installed in an industrial facility?

A: The burners are engineered for installation flexibility, supporting both floor and wall mounting. This allows integration in a wide range of industrial settings, from boilers and kilns to ovens and furnaces, depending on spatial and process requirements.Q: What is the process for installing and commissioning these oil burners?

A: Installation involves securing the burner on a suitable floor or wall mount, connecting fuel and electrical lines, and configuring the automatic control system. Initial commissioning is typically performed by certified technicians to ensure optimal performance and safety adherence.Q: How do the low NOx and low smoke emissions benefit industrial users?

A: Low NOx and low smoke emissions help industries comply with environmental regulations and reduce air pollution. This not only supports social responsibility initiatives but also minimizes the impact on surrounding communities and preserves workplace air quality.Q: What advantages does the monoblock cast iron structure offer over other materials or designs?

A: The monoblock cast iron structure ensures high mechanical strength, longevity, and thermal stability. This design minimizes maintenance requirements and prolongs equipment life, making it well suited for demanding industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Burners' category

|

Kolkata Office

S.L. Sarani,

Gautam Para, Baguiati

Kolkata-700059 ( India )

|

Bangalore Office

No. 11, Old No.298,

9th 'A' Main, 1st Corss,

Chairman Layout, Dodda Bansawadi,

Opp. Shrinidhi Upachar Hotel ,

Bangalore-560043 ( India )

|

|

Ludhiana Office

House No. 3721, Gali No. 7,

Baba Deep Singh Nagar,

Opp.Transport Nagar,

Ludhiana,Punjab,( India )

|

Mumbai Office

Flat No. B/001, Ground Floor,

Krishna Sagar Apartment, Link Road,

Nallasopara, Vasant Nagar,

Vasai (E) Thane-401209

Maharashtra , ( India )

|