- Home Page

- Company Profile

-

Our Products

- Industrial Burners

- Light Oil Burner

- FG 10 Single Stage Light Oil Burner

- FG 14 Single Stage Light Oil Burner

- G 1S Single Stage Light Oil Burner

- GL 20 Single Stage Light Oil Burner

- GL 30 Single Stage Light Oil Burner

- FG 40-2 2 Stage Light Oil Burner

- FG 60-2 2 Stage Light Oil Burner

- FGP 100-2 2 Stage Light Oil Burner

- FGP 120-2 2 Stage Light Oil Burner

- FGP 150-2 2 Stage Light Oil Burner

- FGP 50-2 2 Stage Light Oil Burner

- FGP 70-2 2 Stage Light Oil Burner

- G 2S 2 Stage Light Oil Burner

- FGP 190-3 3 Stage Light Oil Burner

- FGP 250-3 3 Stage Light Oil Burner

- FGP 350-3 3 Stage Light Oil Burner

- FGP 450-3 3 Stage Light Oil Burner

- GX3 3 Stage Light Oil Burner

- Industrial Heavy Oil Burner

- Industrial Gas Burners

- Suntec Fuel Pumps

- Suntec Fuel Pump

- Suntec Fuel Pumps

- Suntec Pump

- Burner Fuel Pump

- Fuel Pump For Industrial Burner

- Suntec Industrial Fuel Pump

- Suntec Oil Burners Pump

- Suntec Industrial Oil Pump

- Suntec Fuel Oil Pumps

- Suntec Fuel Oil Gear Pump

- Suntec Burner Pump

- Suntec AN67B 7251 4P Pump

- TA2C 40107 Suntec Pump

- T3C 106 Suntec Pumps

- E7NA 1069 7P Suntec Pumps

- Hot Water Generator

- Baby Steam Boilers

- Burner Gas Train System

- Siemens Oil Burner Controls

- Siemens Gas Burner Controls

- Siemens Universal Controller

- Industrial Burner Servo Motors

- Gas Governor

- Honeywell Combustion Control Products

- Compact Flame Detector

- Flame Switch Units

- Honeywell Flame Detectors

- Integrated Flame Switches

- Electronic Flame Detector

- Infrared Flame Detector

- Honeywell Flame Detection

- Burner Control System

- Honeywell Burner Control

- Honeywell Wiring Subbase

- Purge Timers

- Honeywell Satronic Burner Controls

- Satronic Burner Controls

- Honewell Satronic Burners Controls For Single Gas

- Photo Cell Flame Detectors

- Sequence Controllers

- Electronic Ignition Devices

- Oil Preheaters

- Conectron Servomotors

- Fuel Delivery System

- Fuel Air Control System

- Pressure Controllers

- Pressure Control For Regulation Of Liquid

- Modutrol Motors

- Spark Ignition Module

- Ignition Transformers for industrial burners

- Fuel Pump For Industrial Burner

- Industrial Gas Regulators

- Motors For Industrial Burners

- Water Boiler

- Burners Controllers

- Solenoid Valves For Industrial Burners

- Servomotors Assembly

- Conectron Motors

- Conectron Servo Motors

- Conectron Air Damper Actuator

- Honeywell Motors

- Siemens Reversing Actuator

- Honewell Servomotors Assembly

- Siemens Servo Motor Dampers Actuators

- Siemens Damper Actuators

- Siemens Actuators

- Siemens Servo Motors

- Siemens Actuators For Oil

- High Speed Damper Actuators

- Siemens SQM9 Actuators

- Siemens Servo Motor Damper Actuators

- Industrial Pressure Switches

- Industrial Burners Nozzles

- Burners Control Box & Base Plate

- Flame Sensor/Photo Cell/UVCell Industrial Burners

- Siemens Burners Photocell

- Industrial Burners UV Cell

- Brahma Photo Cell

- Danfoss Flame Sensors

- Siemens Gas UV Cell

- ECEE Burners Photo Cell

- Siemens Flame Detector

- Siemens Burner Flame Detector

- Blue Flame Detector

- Siemens UV Flame Detectors

- Siemens Flame Sensor

- Siemens UV Photocell

- Siemens Flame UV Cell

- QRI Flame Detectors

- Siemens Flame Sensor RAR

- Siemens Oxygen Sensor

- Burners Diffuser Disc

- Burner Ignition Electrode

- Industrial Burner Filters

- Industrial Burners Pressure Gauges

- Industrial Burners Couplings

- Industrial Burner Connectors

- Burners Thermostat

- Gas Valves

- Our Infrastructure

- Contact Us

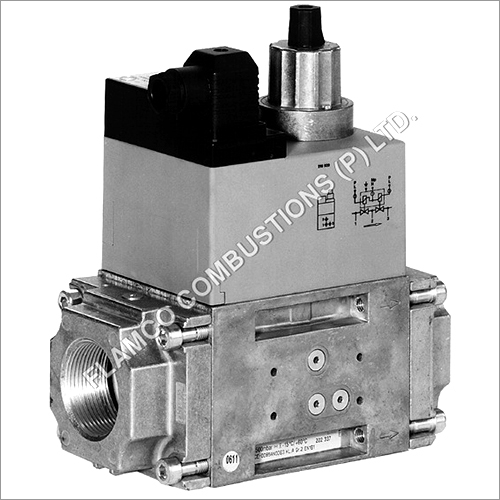

Double Solenoid Valves

1250 INR/Piece

Product Details:

- Operating Voltage 24V DC, 220V AC

- Power Consumption 4.5 VA

- Working Presssure 0.150.8 MPa

- End Connection Threaded

- Material Aluminum Alloy

- Valve Structure Pilot Operated Piston

- Way Type 5/2 Way

- Click to View more

X

Double Solenoid Valves Price And Quantity

- 1250 INR/Piece

- 100-200 Piece

Double Solenoid Valves Product Specifications

- 0.150.8 MPa

- Air

- 128 x 32 x 40 mm

- -5C to 60C

- Silver Gray

- Precision Machined

- 1/4 BSP

- Aluminum Alloy

- 340 g

- Threaded

- 0.150.8 MPa

- Pilot Operated Piston

- -5C to 60C

- 4.5 VA

- Threaded

- 24V DC, 220V AC

- Automation, Pneumatic Systems

- 5/2 Way

Double Solenoid Valves Trade Information

- 100 Piece Per Week

- 1 Week

Product Description

Leveraging upon our technologically-advanced production facility, we are highly engaged in exporting and supplying Double Solenoid Valves to our esteemed customers spread all across the nation. These valves are highly preferable in petrochemical, shipping yards, automobile and nuclear power plants in order to assure unobstructed flow of air and liquid. Furthermore, these Double Solenoid Valves are manufactured under the guidance of vendors' ingenious professionals using premium quality raw materials with the help of innovative technology.

Features:

-

Dimensional accuracy that assure easy installation

- Sturdiness and impeccable performance

- Regulate the flow of fluids

- Excellent finish with compact design

- Ability to withstand high temperature

- Polished with optimum quality materials that assure its corrosion resistance

- Withstand adverse condition

Specifications:

- Max operating pressure

- 0.5 bar (50 kPa)

- Two class A valves in one housing

- DMV-D Fast opening , fast closing

- main flow rate adjustable

- DMV- DLE Slow opening , fast closing

- main flow rate adjustable

- adjustable rapid stroke for pilot gas flow

- Closed position indicator switch K01/1 add -on unit

- EC type test approval as per EC Gas appliance Directive :

- DMV-.../11... CE-0085 AN 2801

- EC type test approval as per EC Pressure EC Pressure Equipment Directive :

- DMV-.../11... CE0036

- Approvals in pother important gas consuming countries

Technical Data

| Type | Solenoid Valves |

| Material | Stainless Steel,Aluminium |

| Media | Water,Gas |

| Temperature of Media | Medium Temperature ,High Temperature |

Precision and Reliability for Automation Systems

These double solenoid valves are engineered for exacting industrial requirements. The precision-machined aluminum alloy body, combined with a corrosion-resistant coating, ensures reliability and durability even in demanding operational environments. The NBR sealing material maintains media integrity under rigorous conditions, while rapid actuation and high-frequency handling boost productivity in automated setups.

Efficient Performance with Superior Control

Equipped with a manual override and pilot-operated piston structure, the valves offer outstanding control flexibility. Continuous duty cycles and low current draw help ensure energy efficiency throughout extended use. The IP65 protection rating safeguards the valve against dust and moisture, while the F-class coil insulation guarantees safe operation in variable ambient temperatures.

FAQs of Double Solenoid Valves:

Q: How does the manual override function benefit automated pneumatic systems?

A: The manual override enables operators to actuate the valve manually during setup, maintenance, or emergencies, ensuring system continuity and facilitating troubleshooting without disrupting the entire automation process.Q: What type of media is suitable for use in these double solenoid valves?

A: These valves are specifically designed for air as the operating media, performing reliably within a media temperature range of -5C to 60C, making them ideal for industrial pneumatic applications.Q: Where are these double solenoid valves commonly installed?

A: These valves are typically mounted in base or direct installations within automation setups, pneumatic control panels, and manufacturing systems that demand rapid and precise air flow management.Q: What is the process for connecting these valves to pneumatic systems?

A: Connection is achieved through threaded end connections compatible with 1/4 BSP port sizes, ensuring secure integration into existing piping and allowing for straightforward installation and maintenance.Q: When should these double solenoid valves be considered for replacement or maintenance?

A: Regular inspection is recommended, especially in environments with harsh operating cycles. Replace seals or the valve assembly when signs of leakage, delayed response times, or inconsistent actuation performance are detected.Q: What are the advantages of the F-class coil insulation and IP65 protection rating?

A: F-class coil insulation enhances thermal safety for extended operation, while the IP65 rating protects the valve from dust ingress and water jets, thus expanding its operational reliability in industrial settings.Q: How does the corrosion-resistant coating contribute to the valves longevity?

A: The specialized coating protects the aluminum alloy body from rust and environmental degradation, ensuring sustained efficiency and minimizing downtimes due to material wear in harsh conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Solenoid Valves For Industrial Burners' category

|

Kolkata Office

S.L. Sarani,

Gautam Para, Baguiati

Kolkata-700059 ( India )

|

Bangalore Office

No. 11, Old No.298,

9th 'A' Main, 1st Corss,

Chairman Layout, Dodda Bansawadi,

Opp. Shrinidhi Upachar Hotel ,

Bangalore-560043 ( India )

|

|

Ludhiana Office

House No. 3721, Gali No. 7,

Baba Deep Singh Nagar,

Opp.Transport Nagar,

Ludhiana,Punjab,( India )

|

Mumbai Office

Flat No. B/001, Ground Floor,

Krishna Sagar Apartment, Link Road,

Nallasopara, Vasant Nagar,

Vasai (E) Thane-401209

Maharashtra , ( India )

|