- Home Page

- Company Profile

-

Our Products

- Industrial Burners

- Light Oil Burner

- FG 10 Single Stage Light Oil Burner

- FG 14 Single Stage Light Oil Burner

- G 1S Single Stage Light Oil Burner

- GL 20 Single Stage Light Oil Burner

- GL 30 Single Stage Light Oil Burner

- FG 40-2 2 Stage Light Oil Burner

- FG 60-2 2 Stage Light Oil Burner

- FGP 100-2 2 Stage Light Oil Burner

- FGP 120-2 2 Stage Light Oil Burner

- FGP 150-2 2 Stage Light Oil Burner

- FGP 50-2 2 Stage Light Oil Burner

- FGP 70-2 2 Stage Light Oil Burner

- G 2S 2 Stage Light Oil Burner

- FGP 190-3 3 Stage Light Oil Burner

- FGP 250-3 3 Stage Light Oil Burner

- FGP 350-3 3 Stage Light Oil Burner

- FGP 450-3 3 Stage Light Oil Burner

- GX3 3 Stage Light Oil Burner

- Industrial Heavy Oil Burner

- Industrial Gas Burners

- Suntec Fuel Pumps

- Suntec Fuel Pump

- Suntec Fuel Pumps

- Suntec Pump

- Burner Fuel Pump

- Fuel Pump For Industrial Burner

- Suntec Industrial Fuel Pump

- Suntec Oil Burners Pump

- Suntec Industrial Oil Pump

- Suntec Fuel Oil Pumps

- Suntec Fuel Oil Gear Pump

- Suntec Burner Pump

- Suntec AN67B 7251 4P Pump

- TA2C 40107 Suntec Pump

- T3C 106 Suntec Pumps

- E7NA 1069 7P Suntec Pumps

- Hot Water Generator

- Baby Steam Boilers

- Burner Gas Train System

- Siemens Oil Burner Controls

- Siemens Gas Burner Controls

- Siemens Universal Controller

- Industrial Burner Servo Motors

- Gas Governor

- Honeywell Combustion Control Products

- Compact Flame Detector

- Flame Switch Units

- Honeywell Flame Detectors

- Integrated Flame Switches

- Electronic Flame Detector

- Infrared Flame Detector

- Honeywell Flame Detection

- Burner Control System

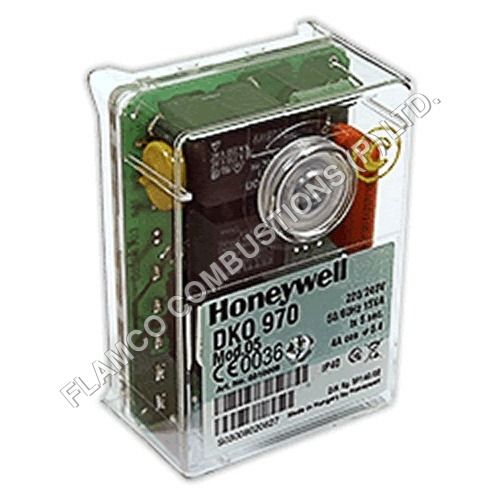

- Honeywell Burner Control

- Honeywell Wiring Subbase

- Purge Timers

- Honeywell Satronic Burner Controls

- Satronic Burner Controls

- Honewell Satronic Burners Controls For Single Gas

- Photo Cell Flame Detectors

- Sequence Controllers

- Electronic Ignition Devices

- Oil Preheaters

- Conectron Servomotors

- Fuel Delivery System

- Fuel Air Control System

- Pressure Controllers

- Pressure Control For Regulation Of Liquid

- Modutrol Motors

- Spark Ignition Module

- Ignition Transformers for industrial burners

- Fuel Pump For Industrial Burner

- Industrial Gas Regulators

- Motors For Industrial Burners

- Water Boiler

- Burners Controllers

- Solenoid Valves For Industrial Burners

- Servomotors Assembly

- Conectron Motors

- Conectron Servo Motors

- Conectron Air Damper Actuator

- Honeywell Motors

- Siemens Reversing Actuator

- Honewell Servomotors Assembly

- Siemens Servo Motor Dampers Actuators

- Siemens Damper Actuators

- Siemens Actuators

- Siemens Servo Motors

- Siemens Actuators For Oil

- High Speed Damper Actuators

- Siemens SQM9 Actuators

- Siemens Servo Motor Damper Actuators

- Industrial Pressure Switches

- Industrial Burners Nozzles

- Burners Control Box & Base Plate

- Flame Sensor/Photo Cell/UVCell Industrial Burners

- Siemens Burners Photocell

- Industrial Burners UV Cell

- Brahma Photo Cell

- Danfoss Flame Sensors

- Siemens Gas UV Cell

- ECEE Burners Photo Cell

- Siemens Flame Detector

- Siemens Burner Flame Detector

- Blue Flame Detector

- Siemens UV Flame Detectors

- Siemens Flame Sensor

- Siemens UV Photocell

- Siemens Flame UV Cell

- QRI Flame Detectors

- Siemens Flame Sensor RAR

- Siemens Oxygen Sensor

- Burners Diffuser Disc

- Burner Ignition Electrode

- Industrial Burner Filters

- Industrial Burners Pressure Gauges

- Industrial Burners Couplings

- Industrial Burner Connectors

- Burners Thermostat

- Gas Valves

- Our Infrastructure

- Contact Us

Fuel Delivery System

Product Details:

- Mechanical Life 1,000,000 cycles

- Thread size M12 x 1.5

- Max Pressure 4 Bar

- Function Efficient fuel transfer and injection

- Working Temperature -40C to +85C

- Product Type Fuel Delivery System

- Max. Current 5.5A

- Click to View more

X

Fuel Delivery System Price And Quantity

- 100-200 Piece

Fuel Delivery System Product Specifications

- Silver & Black

- Automotive engines, industrial machinery

- -40C to +85C

- Efficient fuel transfer and injection

- 5.5A

- 12V

- 4 Bar

- Standard/Custom (refer datasheet)

- 2.3kg

- 220W

- Analog 0-5V

- M12 x 1.5

- 0 - 4 Bar

- 1,000,000 cycles

- Fuel Delivery System

- IP54

Fuel Delivery System Trade Information

- 1000 Piece Per Week

- 1 Week

Product Description

Fuel delivery System

Model No - VR400-vf

The VR400-vf is used in all condensing or non condensing premix burner applications of large capacity (150 kW to 500 kW) . It consists of a VR400 VA combivalve with pneumatic gas / air regulator assembled directly downstream or upstream of the venturi (the fan mounted downstream maximizes the capacity of the gas valve and ensures full premixing of the gas / air mixture ).

Modulation is obtained by varying the amount of airflow (usually by using a variable speed fan ). The gas flow will follow the airflow in a predetermined ratio thanks the gas / air pneumatic servo regulator .

Exceptional Material and Durability

Constructed with premium aluminum and steel, the fuel delivery system resists wear, corrosion, and harsh conditions. O-ring and gasket seals further enhance protection, contributing to an impressive mechanical life of up to a million cycles. These characteristics support reliability and stability in both automotive and industrial settings.

Advanced Performance and Compatibility

Boasting a flow rate of 115 LPH and pressure range up to 4 Bar, the system achieves precise and efficient fuel transfer and injection. Its integrated filter provides clean fuel, crucial for optimal engine performance. The product caters to standard and customized sizing needs, supporting various applications from vehicles to machinery.

FAQs of Fuel Delivery System:

Q: How do I install the fuel delivery system for optimal performance?

A: To ensure optimal performance, mount the system using either the inline or flange configuration, as suitable for your engine or machinery. Refer to the datasheet for correct sizing and secure the waterproof 3-pin connector to a safe 12V power supply. Proper sealing with O-rings and gaskets is essential to prevent leaks.Q: What types of fuels are compatible with this fuel delivery unit?

A: This system is designed for versatility, supporting petrol, diesel, and biofuels. Its integrated fine micron filter and corrosion-resistant materials ensure stable operation regardless of the fuel type, making it suitable for wide-ranging automotive and industrial fuel applications.Q: When should the fuel filter be inspected or replaced?

A: Regular inspection of the integrated fine micron filter is recommended during routine maintenance intervals, particularly in high-contamination environments. The filter safeguards engine functionality, so timely cleaning or replacement helps maintain efficiency and prolong system longevity.Q: Where can this fuel delivery system be applied?

A: The unit is suitable for automotive engines as well as industrial machinery, fitting various layouts with standard and custom sizes. It accommodates conditions ranging from -40C to +85C and is ideal for OEMs, distributors, exporters, and suppliers across India.Q: How does the waterproof connector benefit usage in harsh conditions?

A: The three-pin waterproof connector ensures reliable electrical connectivity, protecting against moisture and dust ingress. This design feature enhances operational stability and minimizes electrical faults in demanding environments, consistent with the IP54 protection rating.Q: What are the main benefits of using this fuel delivery system?

A: Key advantages include efficient fuel transfer, quick response time (<10 ms), compatibility with multiple fuel types, robust sealing, and long mechanical life. Low operational noise (<70 dB) and reliable analog signal output (05V) further support performance and diagnostics.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Honeywell Combustion Control Products ' category

|

Kolkata Office

S.L. Sarani,

Gautam Para, Baguiati

Kolkata-700059 ( India )

|

Bangalore Office

No. 11, Old No.298,

9th 'A' Main, 1st Corss,

Chairman Layout, Dodda Bansawadi,

Opp. Shrinidhi Upachar Hotel ,

Bangalore-560043 ( India )

|

|

Ludhiana Office

House No. 3721, Gali No. 7,

Baba Deep Singh Nagar,

Opp.Transport Nagar,

Ludhiana,Punjab,( India )

|

Mumbai Office

Flat No. B/001, Ground Floor,

Krishna Sagar Apartment, Link Road,

Nallasopara, Vasant Nagar,

Vasai (E) Thane-401209

Maharashtra , ( India )

|